Thermal break aluminum win-door machine and upvc win-door machine

21 Aug, 2021Most of the thermal break aluminum doors and windows machine are used in the processing of thermal break aluminum doors and windows, and most of the upvc doors and windows machine are used in the processing of upvc doors and windows. According to detailed classification, there are two types of door and window machine: sawing machine and milling machine. Perhaps some buyers think that these two machine can be used in common? In terms of power, the cutting saw blade of the thermal break aluminum ......

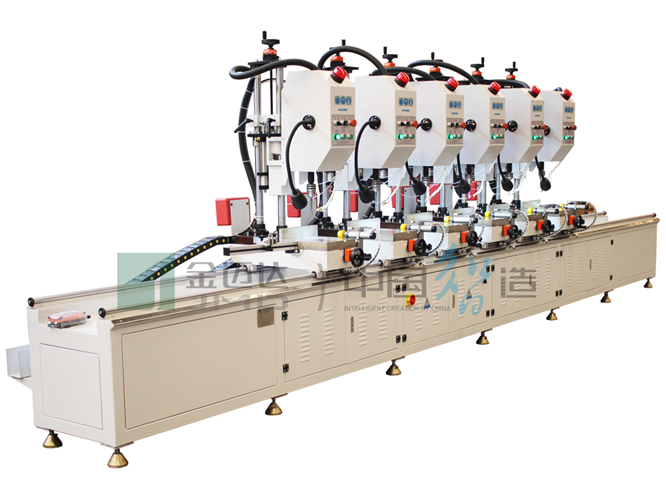

About Multi Head Drilling Machine

11 Aug, 2021This machine adopts 6 set drilling head, each head adopts three-axis drill pack for drilling holes, which can be combined to use according to the hole diameter on the drilling bit rocker arm and center distance. Six sets drilling head was installed on the bed guide rail,which can move right-left and pneumatic locking arbitrarily;Six sets drill bit drilling holes can be either single action or linkage, especially fit for mass production;Head feeding adopts cylinder and damping cylinder, which ......

Five Advantages of Thermal Break Aluminum Doors and Windows

28 Jul, 20211. Energy saving and environmental protection Thermal break aluminum doors and windows have good airtightness. In the hot summer, the indoor temperature is often higher than the outdoor temperature. If the doors and windows inside the home are not sealed well, the indoor temperature will drop relatively slowly, and the air conditioner will be turned on. The time will be longer. So on the contrary, if the doors and windows of the house are tightly sealed, the indoor temperature will drop fast......

Advantages of aluminium double head cutting saw

23 Jul, 20211. The double-head cutting saw is a profile cutting tool used in the production of doors and windows. It is suitable for cutting aluminum and plastic profiles. The transmission and feed of the sawing machine are controlled by a numerical control system. The cutting size has high precision, simple operation, reliable performance, and advanced technology. The cutter adopts cemented carbide circular saw, which has fast cutting speed and high production efficiency. It is an ideal equipment for the ......

Maintenance of aluminum doors and windows machine

13 Jul, 20211. Check mechanical parts and fasteners to prevent loosening. Every conveying part must be regularly lubricated, and the movable head rail must be regularly lubricated every week. The oil cup keeps a certain amount of oil, the circulating water of the water tank is replaced every day, the water tank is cleaned regularly every week, the nozzle is frequently checked, and the plug is found and cleaned in time. The working surface and jaws of the board fitter, the upper and lower pressing pliers sh......

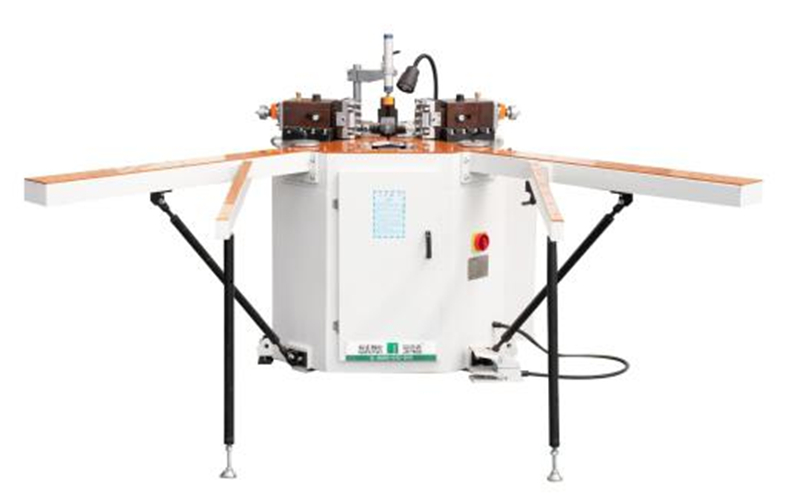

About Corner Crimping Machine

07 Jul, 2021Principle and structure: 1. Main componentsThe corner crimping machine is composed of main parts such as body, worktable, positioning cylinder, riveting device, corner crimping cylinder, corner crimping slide, electric control panel, foot switch and so on. The pneumatic system consists of solenoid valves, pressure gauges, mist, water separators, etc. The hydraulic system is composed of hydraulic pump, solenoid valve, high pressure hose, hydraulic relay, etc.2. Working principleThe corne......

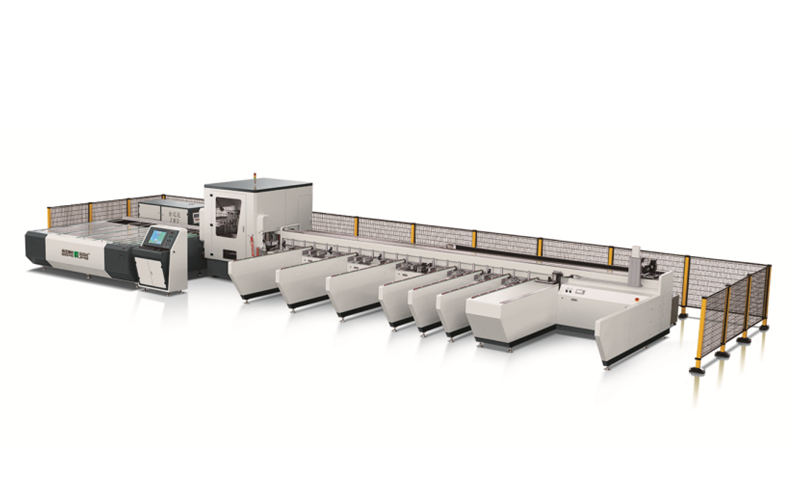

How to Automatic production of window and doors (2)

30 Jun, 2021Cutting is the first process of all equipment. The angle, accuracy and perpendicularity of cutting will affect the subsequent production quality of doors and windows. Therefore, cutting is also the most important link in the production of doors and windows. The current thinking of JMD door and window equipment company is to complete the automation of the first process, make the first cutting process to the extreme, and then break through the subsequent processing process. Each process purchase......

How to Automatic production of window and doors (1)

30 Jun, 2021To realize the automatic production of doors and windows is a big trend in the door and window industry. Only through the transformation and upgrading of the industry related to the door and window industry can we realize the networking of doors and windows from the aspects of design, ordering, purchasing, production, packaging, transportation, installation, etc., and the ERP program and MES control system can be connected to realize the true automatic production factory of doors and windows. T......

About thermal break aluminum alloy windows and doors

28 Jun, 2021Advantages of thermal break aluminum alloy windows and doors: 1. Reduce heat conduction: The use of insulated thermal break aluminum alloy profiles and hollow glass structure effectively reduce the heat conduction through doors and windows. 2. Prevent condensation: The temperature of the inner surface of the profile with heat insulation strips is close to the indoor temperature, reducing the possibility of indoor moisture condensation on the surface of the profile due to oversaturation. 3. ......

How to judge the quality of aluminum door and window machinery?

23 Jun, 20211. From the point of view of materials, the thickness, strength and oxide film of high-quality aluminum door and window machinery should meet relevant standards. The wall thickness should be greater than 1.2 mm, the tensile strength should reach 157 Newtons per square millimeter, the yield strength should reach 108 Newtons per square millimeter, and the oxide film thickness should reach 10 microns. If it does not meet the above standards, it is a low-quality aluminum alloy door and window equip......

Why can aluminum alloy doors and windows occupy the market?

17 Jun, 2021Doors and windows made of aluminum alloy extruded profiles as frames, stiles, and fan materials are called aluminum alloy doors and windows, or aluminum doors and windows for short. Including aluminum-wood composite doors and windows that use aluminum alloy as the base material of the load-bearing rod (the rod that bears and transfers its own weight and load) and wood and plastic, referred to as aluminum-wood composite doors and windows. The quality of aluminum alloy doors and windows can be rou......

What equipment is needed to open a door and window factory

11 Jun, 20211. Double head cutting sawThe double-head cutting saw is used to cut aluminum alloy profiles. The accuracy of sawing directly affects the quality of doors and windows, so double-head saws are essential equipment for the production of doors and windows. There are many varieties of double-head cutting saws on the equipment market. For example: Manual, digital display, CNC. Specially cut 45 degrees, there are also 45 degrees and 90 degrees. The price ranges from tens of thousands to hundreds of th......